Q2 SandShark

Description

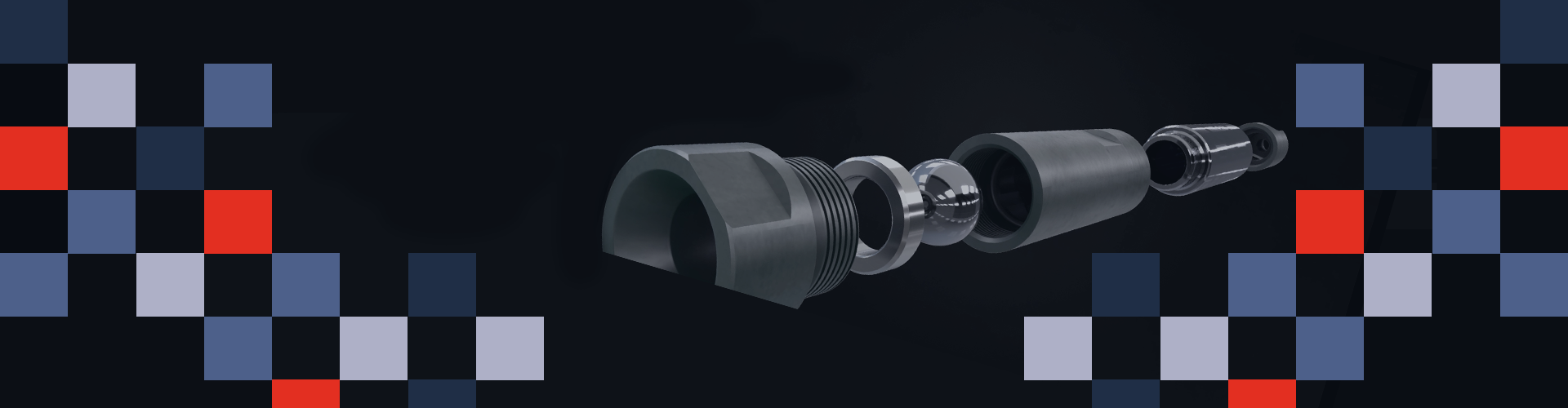

A fully engineered solids fallback protection system solution for preventing “pump sticking” solids accumulation in the tubing string above a sucker rod pump. The SandShark™ is a high-performance downhole solution for controlling the risk of troublesome solids settling on top of a pump after a shut down.

Value Features

- Patent pending design.

- See Southwest Petroleum Short Course paper (2025042) “Solids Fallback Protection Tool for Sucker Rod Pumping.”

- Protects stuck sucker rod pumps from solids that would have normally accumulated in the tubing above the pump.

- Designed and built around a standard 2-7/8″ (73.00mm) EUE L-80 tubing joint, with unrestricting, 2.441″ tubing drift internal diameter.

- Innovative eccentric chamber is used to capture and retain solids “out of harms way” downhole while the pump is operating.

- Does not restrict the annular flowby area.

- A simple system solution that uses proven RFG Long-Guided Stabilizer Bars and RFG Box-Guides with long MP Polymer® rod guides to force fluid into the solids separation chamber during the pump’s down stroke.

- Multiple SandShark™ tools can be run in series to increase the solids containment capacity.

- Fully serviceable/re-runnable.

Use in Wells to

- Maximize sucker rod pumping performance with solids laden produced fluids, especially in combination with WhaleShark™ gas separator, MudShark™ extended dip tube solids separator, SharkTAC™ tubing anchor, and Q2-Flow™ + SandTwister™ pump.

- Maximize sucker rod pump and rod run-life and reliability.

- Reduce solids related stuck pump risks and to avoid pump start-up issues after a shut down.