Q2 MudShark

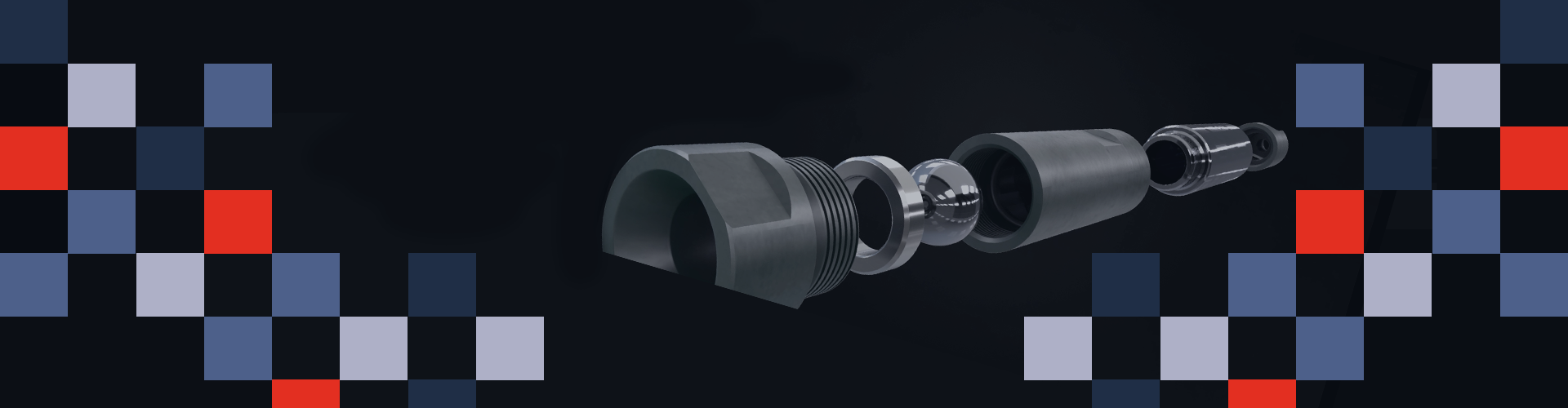

Description

A fully engineered, multi-staged sequential solids separation system designed to safeguard sucker rod pumps for when using Extended Dip Tube BHA configurations. The MudShark™ delivers the industry’s highest-performance downhole solution for mitigating risks from problematic produced solids, significantly extending pump run life—and it’s the only solids separation system compatible with Extended Dip Tube BHA setups.

Value Features

- Patent pending design that uniquely “busts up” solids slugs and then separates solids.

- Protects the sucker rod pump from damaging solids.

- Engineered for Extended Dip Tube BHA systems.

- Innovative eccentric fiber reinforced thermoplastic cups, mounted on a 3/8″ fiber reinforced thermoplastic rod, separate, capture and retain solids “out of harms way.”

- Sucker rod pumping cyclical flow improves separation efficiency (during the downstroke when the standing valve is closed, solids settle into the cups).

- Minimal pressure loss across cups (28 cups per insert).

- Multiple MudShark™ inserts can be run by inserting one into each Extended Dip Tube tubing joint for increasing the downhole solids containment capacity.

- Optional reverse flow control valve.

Use in Wells to

- Maximize sucker rod pumping performance with solids laden produced fluids and using Extended Dip Tube BHA’s.

- Use in combination with WhaleShark™ gas separator, SharkNET™ self-cleaning solids filtering systems, SharkGUT™ horizontal solids separator, SandShark™ pump solids fallback protection system, SharkTAC™ tubing anchor and Q2-Flow™ + SandTwister™ pump.

- Maximize sucker rod pump and rod run-life and reliability.

- Reduce solids related stuck pump risks and to avoid pump start-up issues after a shut down.