Q2 WhaleShark

Description

The WhaleShark downhole separator is an innovative and unique technology that bring high performance with lower risk for gas and solids separation. The WhaleShark’s patent pending design uses an open top mouth collector concept that allows liquid to simply and efficiently fall into it. This unique design eliminates performance limiting traditional separator side intake ports.

Advantages

You are buying a better result,

not a separator:

1. higher average pump fillage = more production

2. more consistent pump fillage = protects pump and sucker rods

3. less slug flow = reduced solids production, easier solids separation

4. more solids separation = momentum/ gravity separation beats cyclonic

5. no packer or cup seal = less operational risk

Features

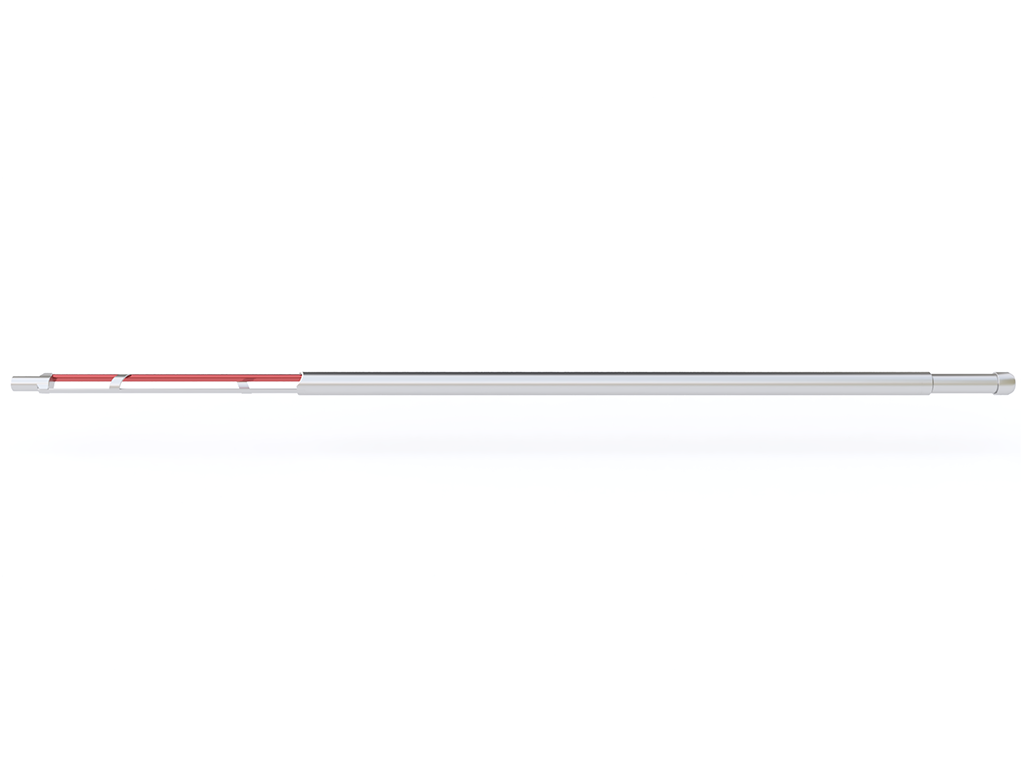

1. Upward facing intake takes advantage of liquid falling backwards

When gas and liquid travel up a wellbore, the liquid phase frequently falls backwards (this is called slippage or liquid reversals between the gas and liquid phases). A large-mouth upward facing separator intake can easily collect the falling liquid, which results in higher and more consistent pump fillage. A poor-boy side intake can not collect falling liquid!

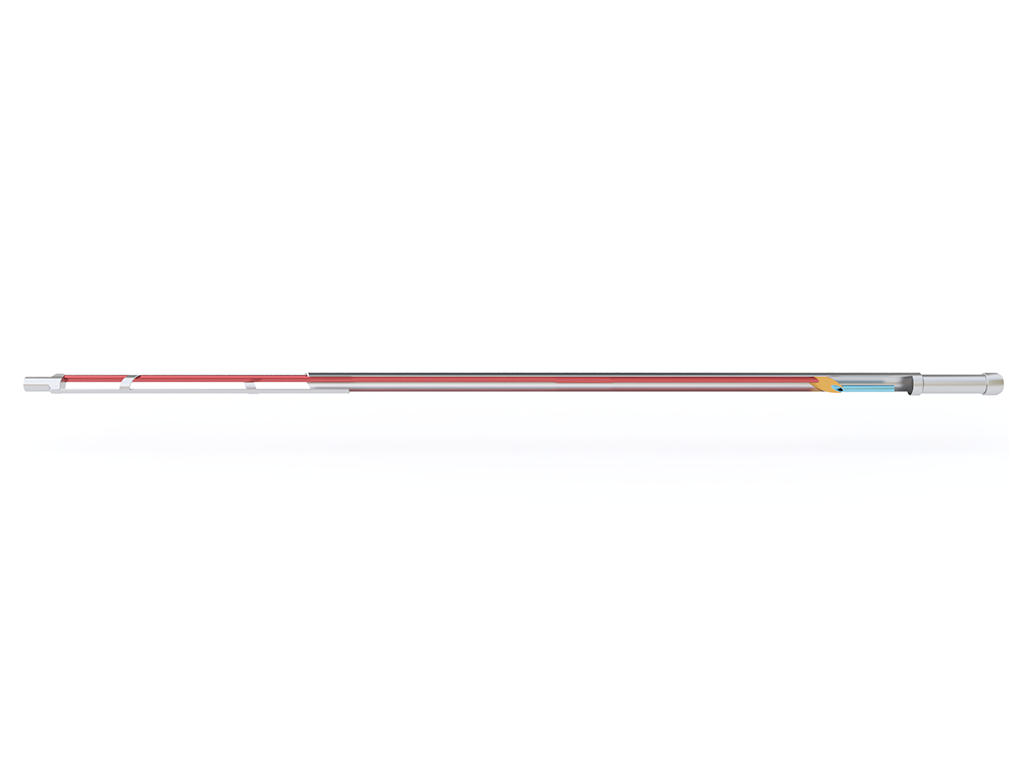

2. Separation Region unique shape = gas escapes more easily

There is no annulus in the WhaleShark’s Separation Region, as the pump intake tube has been moved to the side. Gas escapes more easily with nothing in the center, so liquid then simply falls back into the large-mouth

collector intake. This is the only separator that is not limited by gas bubble rise velocity. Gas escaping more easily means it can handle slug flows!

3. No packer or cup seals, its packerless

Less operational risk/cost installing/retrieving; less cost servicing.

Why other separators under-perform:

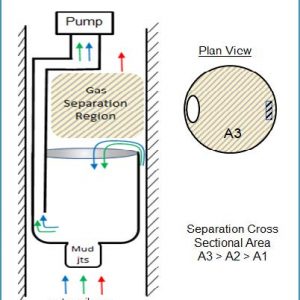

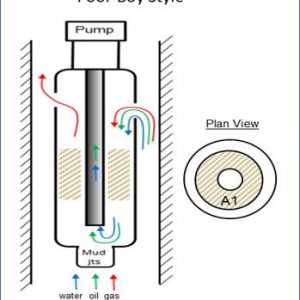

Poor-Boy separator side Intakes are limiting

Gas velocity in the annulus beside a poor-boy makes it difficult for liquids to enter a side intake. Trade-off is a smaller cross-sectional area for separation inside the separator (A1 = small) and therefore less separation capacity.

They can’t handle slug flows = lower and inconsistent pump fillage

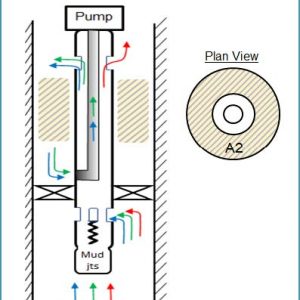

Slugging is very common in horizontals (especially toe-up trajectories) and causes frequent high gas velocities, resulting in inconsistent pump fillage and solids transportation to the pump. A poor-boy’s side intake is not slug flow tolerant. A packer-style suffers from high turbulence through separator and the side discharge into the annulus; turbulence creates smaller gas bubbles that are much harder to separate.

They all use an annulus for separation, which limits capacity

Gas has a tougher time escaping up an annulus, whereas the WhaleShark’s Separation Region has no annulus

and has the largest cross-sectional area for separation over all others.

Packer-Style separators have limited solids separation capacity

Much easier to separate out solids after the gas has been separated, not before!