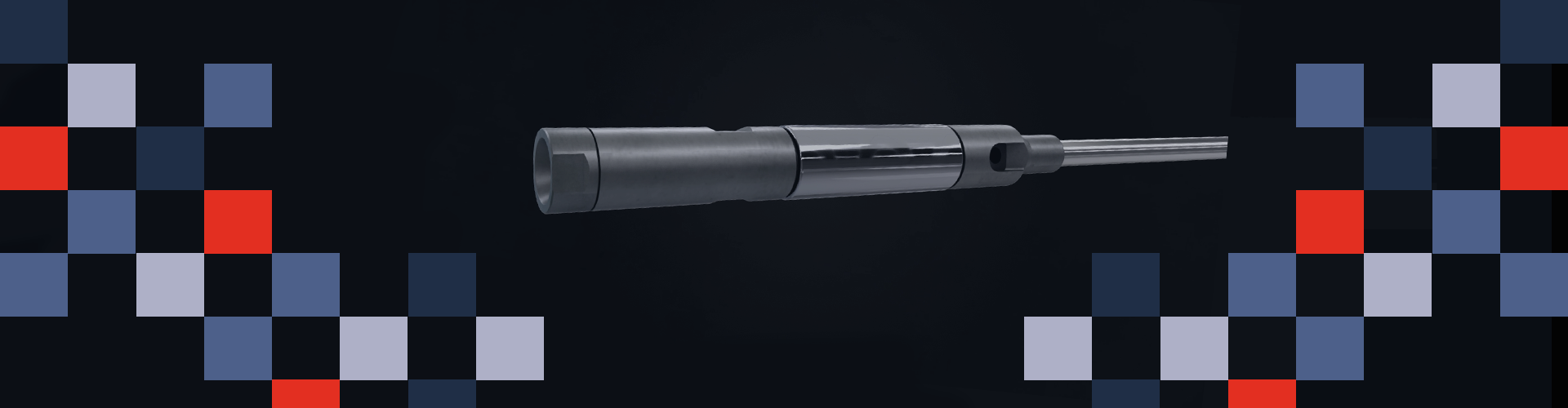

Q2 ALS specializes in the assembly, repair and design of Down Hole Rod Pumps and manufacturers a complete product line of barrels, plungers, fittings, accessories and heat-treated tubing needed for down hole pump installations. Q2 ALS provides specialized services with a fully equipped chrome shop facility plus spray metal and heat induction services.

Sales & Service

We have 30+ field locations strategically located through-out Western Canada the the United States to provide our customers with real time technical solutions utilizing decades of experience and training from our field personnel.

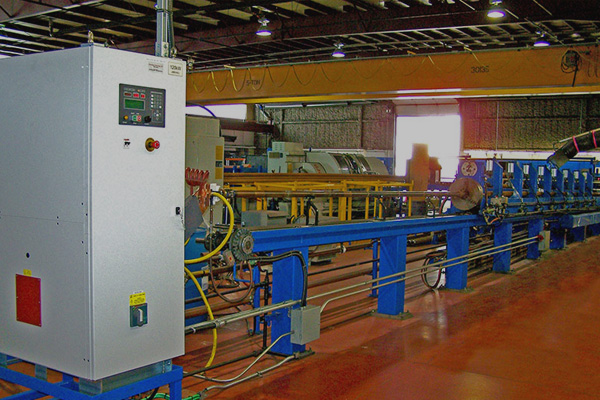

Manufacturing

We offer world class manufacturing in our new 80,000 sq. ft. state of the art facility. We offer in-house chroming, spray metal welding, heat treating and CNC’s.

Chrome Plating

Q2 Artificial Lift Services’ hard chrome plating process uses a proprietary high-speed hexavalent formula with important advantages over conventional hard chrome plating. This process also incorporates a travelling anode system that results in superior chrome plate adhesion and even deposition over the length of the barrel.

Wear resistance, Low co-efficient of friction, Corrosion resistance. This leading-edge process provides a high micro crack density. The micro cracks are shorter, shallower and are not continuous from substrate to surface. Effective porosity is reduced to less than 15% from greater than 25% for conventional hard chromes.

As a result, Q2 Artificial Lift Services’ hard chrome plate has increased corrosion resistance, a low coefficient of friction, and higher hardness, 70 HRC typical, enabling it to perform well in conditions where conventional chrome plated products are not typically recommended.

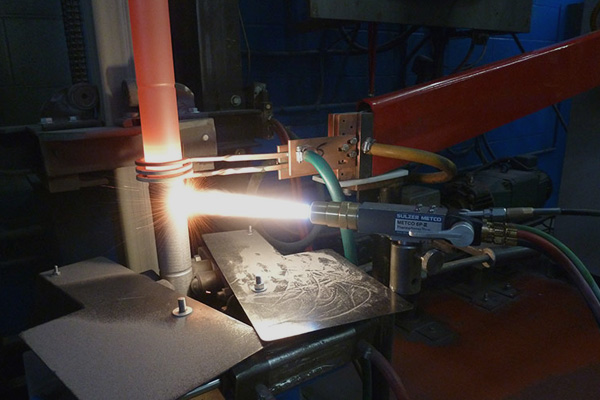

Spray Metal Welding

Q2 Artificial Lift Services’ spray welding process applies thermal spray and fuse coatings using proprietary mechanized equipment assuring uniform hardness and thickness of the coatings to all Spray-metal plungers, Spray Metal valve rods, Pull tubes, and Spray metal polish rods.

Shot blasting of all products prior to coating cleans and coarsens the metal’s surface area for maximum bond integrity.

Proven combustion powder thermal spray system maintains constant supply for consistent coating results over high-volume production runs. Induction fusing to 1900ºF – 2000ºF using a high frequency coil ensures complete and uniform fusion and a superior metallurgical bond to the substrate.

The self-fluxing alloy powders used are nickel based for excellent corrosion resistance. They contain chromium, boron, and silicon for increased strength, toughness, hardness, and wearability. Upgraded Tungsten Carbide powder has 40% carbide content for extreme abrasion resistance.

The fully dense, impermeable coating micro-structure is highly resistant to corrosion and is ground to tight tolerance and a fine finish. Spray metal hardness typically up to 60 HRC and the upgraded Tungsten Carbide spray metal hardness typically up to 65 HRC.

Components Machining (CNC)

Q2 Artificial Lift Services has a full suite of the latest CNC, CNC milling and machining capabilities to build all of your required fittings and accessories. We manufacture steel, stainless steel, monel, and brass fitting for all of the different and demanding applications that our equipment is run in.

Heat Treating

Heat treating is a process used to alter the physical, and sometimes chemical properties of a material, where the most common application is metallurgical.

Heat treatment involves the use of heating, to extreme temperatures, to achieve a desired result such as hardening of a material. Q2 Artificial Lift Services’ Heat-treating technique utilizes case hardening, precipitation strengthening, tempering, normalizing and quenching.

It is noteworthy the term heat treatment applies only to processes where the heating is done for the specific purpose of altering properties intentionally.